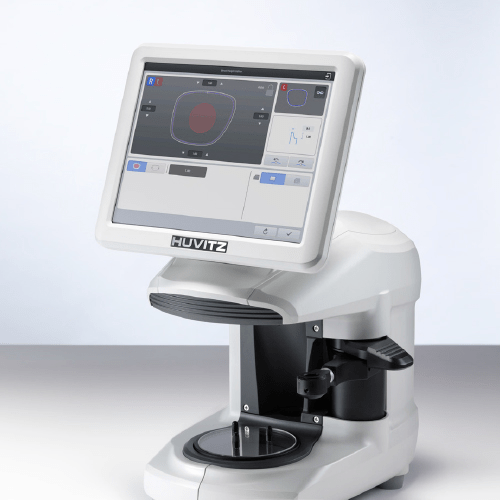

HFR-8000X

Tracer

Frame reader that scans quickly and precisely with high-resolution, 3D scanning

- 16,000pts high-resolution scanning

- 3D smart scanning

- Special types of frames can be scanned

MENU

Explore Details

16,000pts high-resolution scanning

HFR-8000X provides speedy scanning with high-resolution of 16,000pts by adopting the latest motor control platform and digital signal processing technology

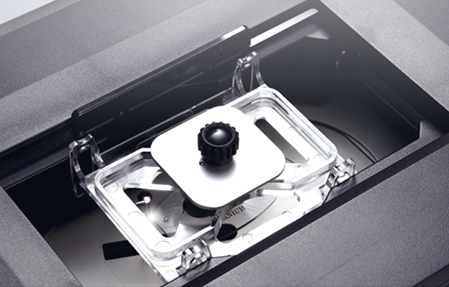

3D smart scanning

Large-curved frames such as goggles, half-rimmed/full-rimmed, and those made of Ultem material are scanned in true-to-life 3D with precise angle recognition of the frame shape.

Special types of frames can be scanned

HFR-8000X can accurately scan complex and challenging shapes such as concave forms, sharp edges, and narrow-width frames without any issues.

Huvitz MEMBERS

더 많은 안과컨텐츠를 원하신다면

휴비츠멤버스에 가입하세요.

Specifications

1. Tracing Type

Automatic 3D binocular tracing

2. Tracing Mode

Auto, Semi-auto (Manual tip-positioning)

3. Tracing Size

Frame ø16.0~92.0mm, Pattern ø16.0~84.0mm

4. Frame Material

Metal, Hard plastic, Soft plastic, Ultem

5. Data Processing

FPD, Frame Curve, Circumference, 3D Angle Concave Shape (Demo lens)

6. Dimensions / Weight

284(W) x 320(D) x 190(H)mm / 8kg

7. Power Supply

AC 100 – 240V, 50 / 60Hz

8. Power Consumption

32W

* Specification and design are subject to change without notice.

Related Products

FAQ

Q. What tracing modes does the HFR-8000X support?

A. The HFR-8000X offers two tracing modes—Auto mode and Semi-auto mode—to enhance flexibility depending on the working environment and required level of precision. In Auto mode, the device automatically scans the entire frame, enabling fast and efficient measurement. In Semi-auto mode, the user manually specifies the initial position of the measuring tip (manual tip positioning) before starting the scan. This mode is especially useful for precise measurement of specific areas or for setting the initial starting point on frames with special or complex shapes. The traceable range is approximately 16.0–92.0 mm for frame diameter and 16.0–84.0 mm for pattern diameter.

Q. Can the HFR-8000X scan frames made of special materials?

A. Yes. The HFR-8000X is a material-friendly device capable of accurately scanning a wide range of materials, including Ultem, metal, and hard/soft plastics.

Even complex and challenging shapes—such as high-curve (goggle) frames, semi-rimless or rimless frames, concave shapes, and narrow frames—are precisely traced without errors using 16,000-point high-resolution scanning and digital filtering technology.

Q. Who is the HFR-8000X suitable for?

A. The HFR-8000X is ideal for optical shops and professional labs that require highly accurate frame data and aim to minimize processing errors or rework. It delivers consistent and reliable results even for complex frames and high-difficulty lens processing, supporting a high-confidence working environment.

Q. How is data connectivity and compatibility with other devices handled on the HFR-8000X?

A. The HFR-8000X supports integration via the Huvitz HERA Intraworks network solution and OMA-based connectivity, allowing flexible data exchange across various system environments. Tracing data and processing information can be directly transmitted to Huvitz edgers, significantly improving workflow efficiency and system compatibility.

Q. What are the processing speed and precision of the HFR-8000X?

A. The HFR-8000X achieves fast and accurate data acquisition through 16,000-point high-resolution scanning, powered by the latest motor control platform and digital signal processing technology. From high-curve goggle frames to semi-rimless or rimless frames, Ultem materials, concave shapes, sharp edges, and narrow frames, even the most complex forms are scanned precisely into true-to-life 3D data.