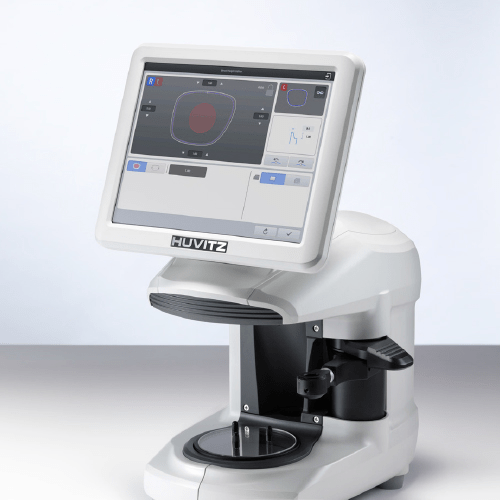

HPE-910

Lens Edger

Premium lens edger with step bevel, perfectly processing high-curve sports goggles

- Fast processing speed is achieved

- Achieving perfect fitting is possible by combining 7 different step bevel types and 5 edging styles

- Retouch Mode can be utilized in a smart way

MENU

Explore Details

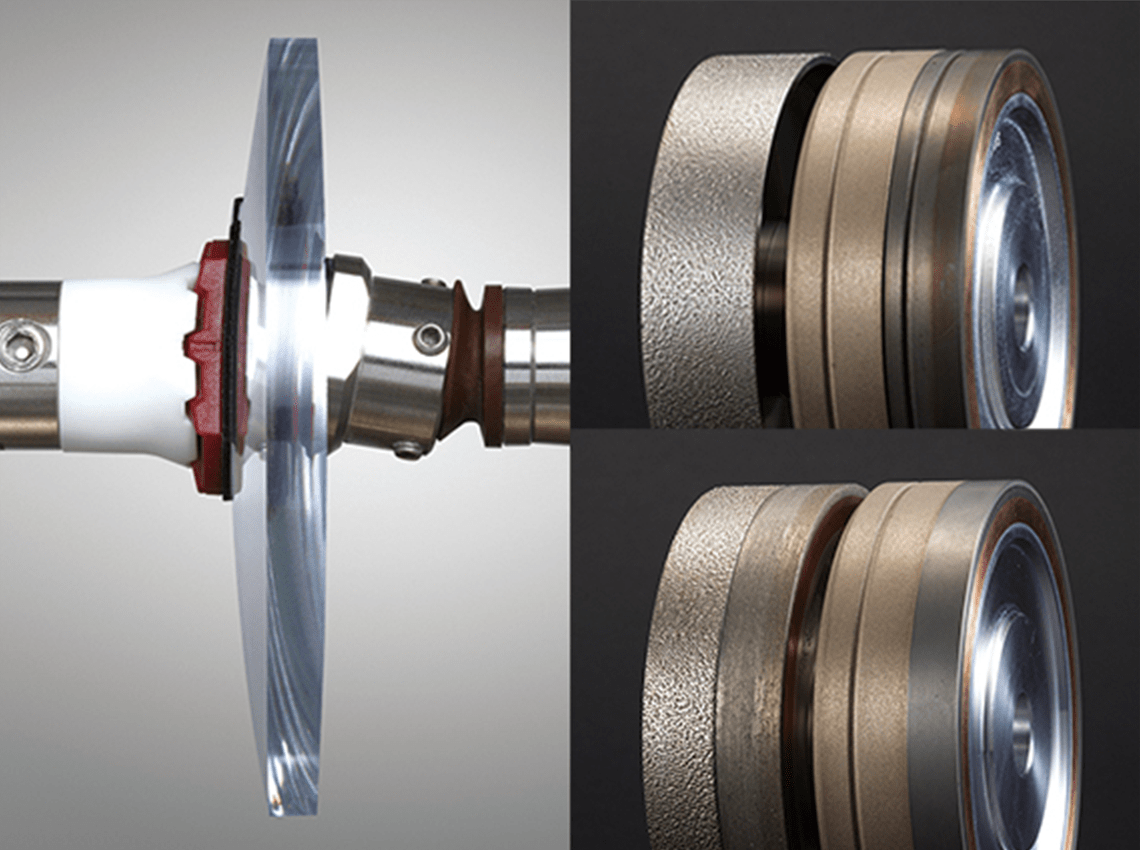

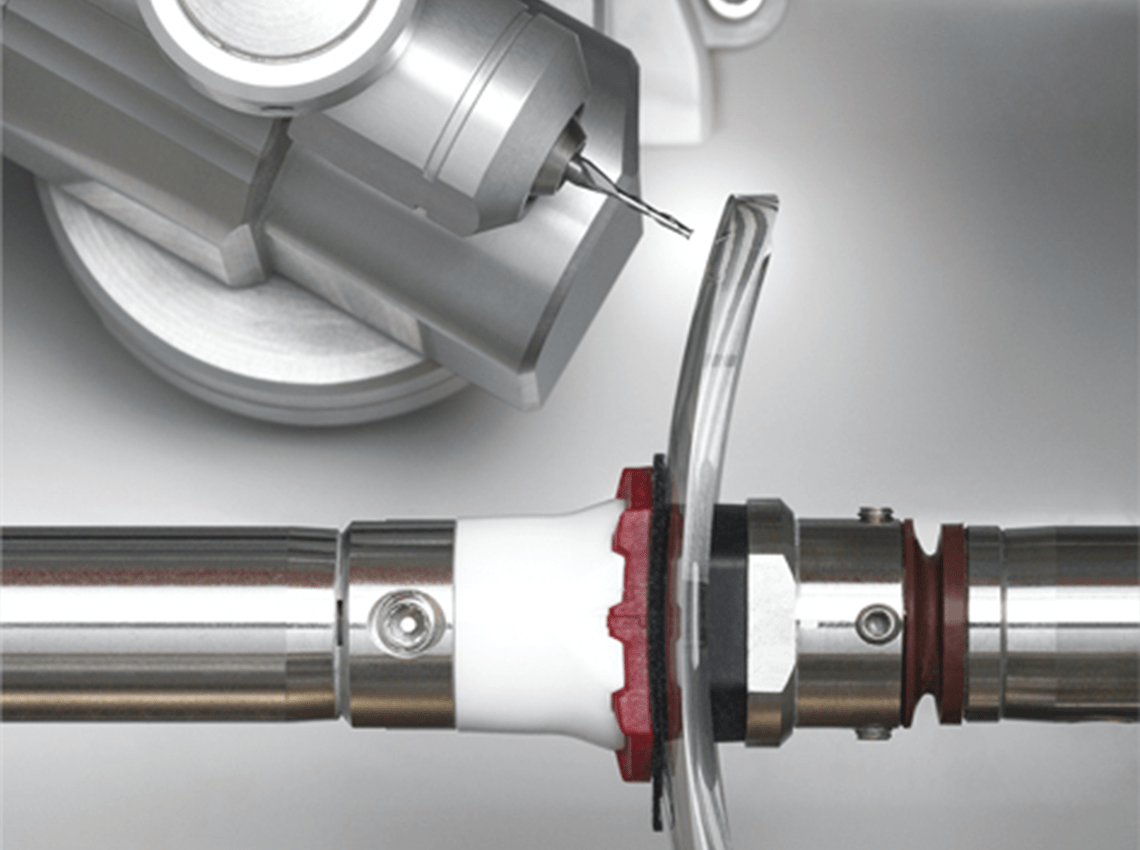

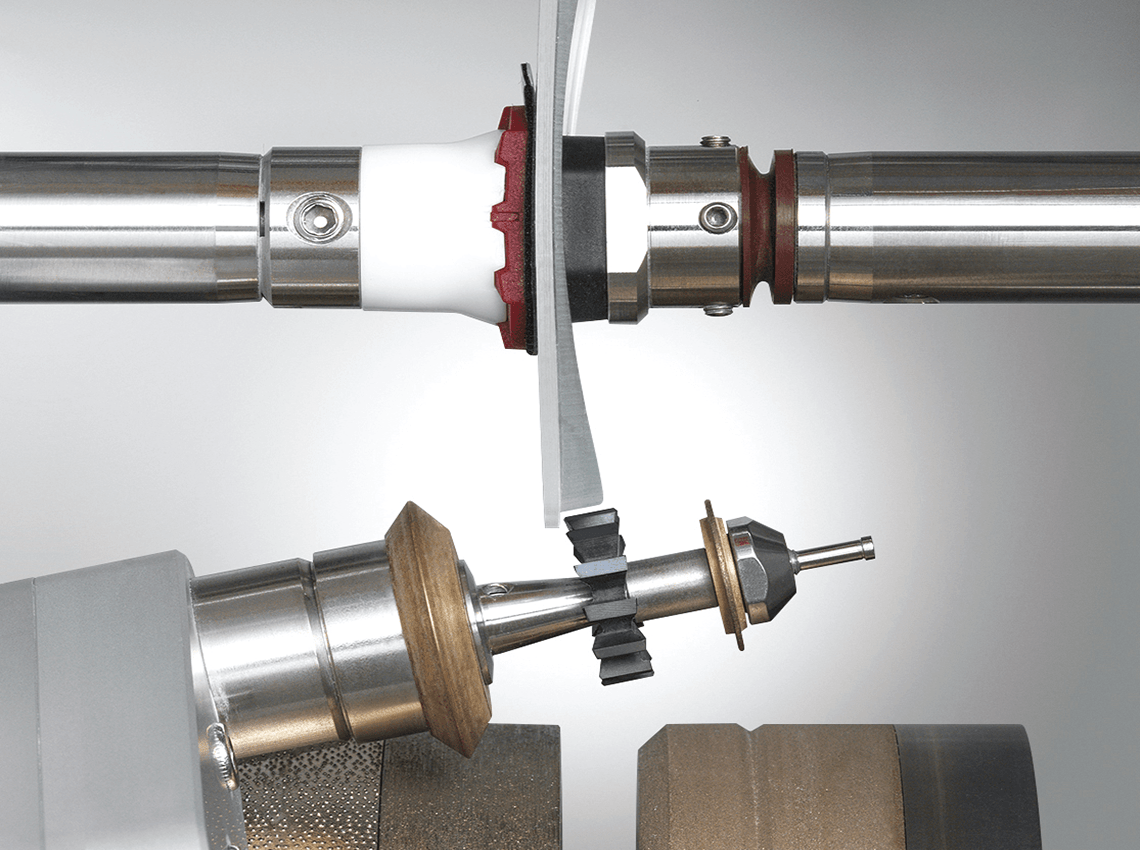

Fast processing speed is achieved

The perceived processing speed is significantly reduced by the ultra-fast lens movement speed, powerful wheel motor made of high-strength material, and fast drill rotation speed.

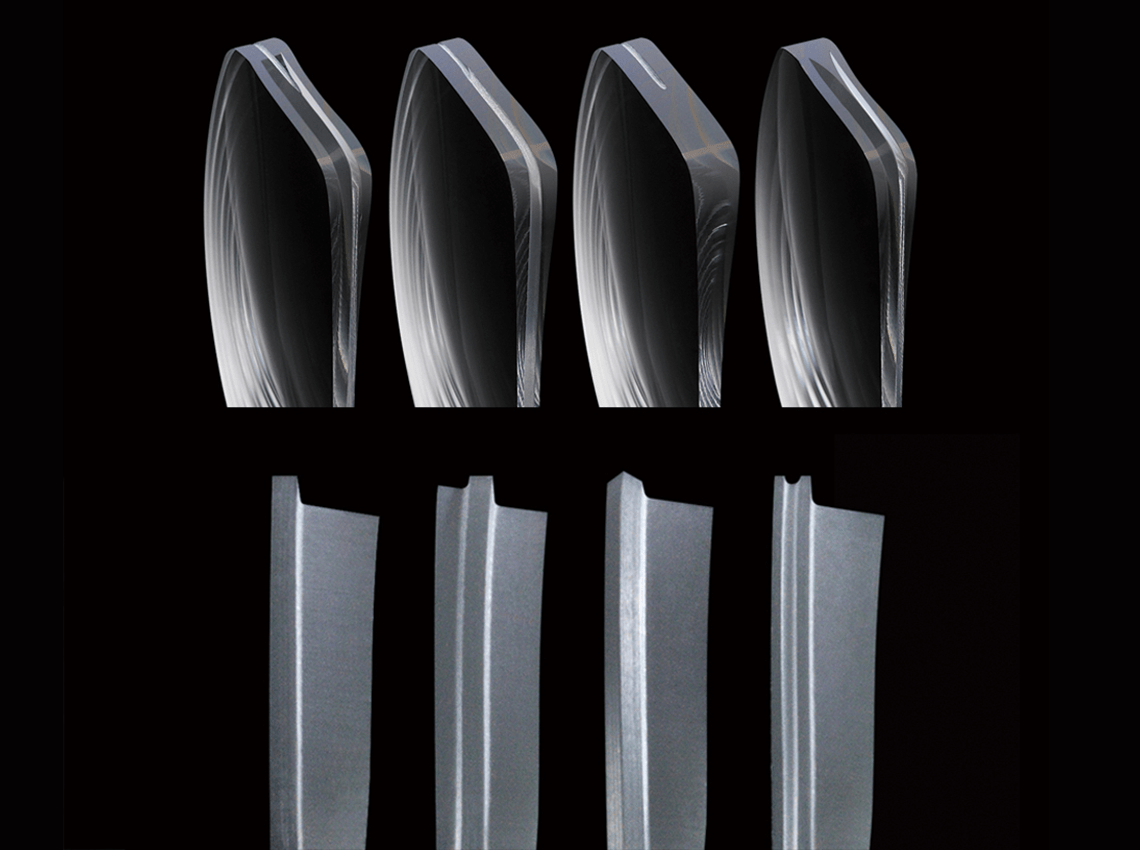

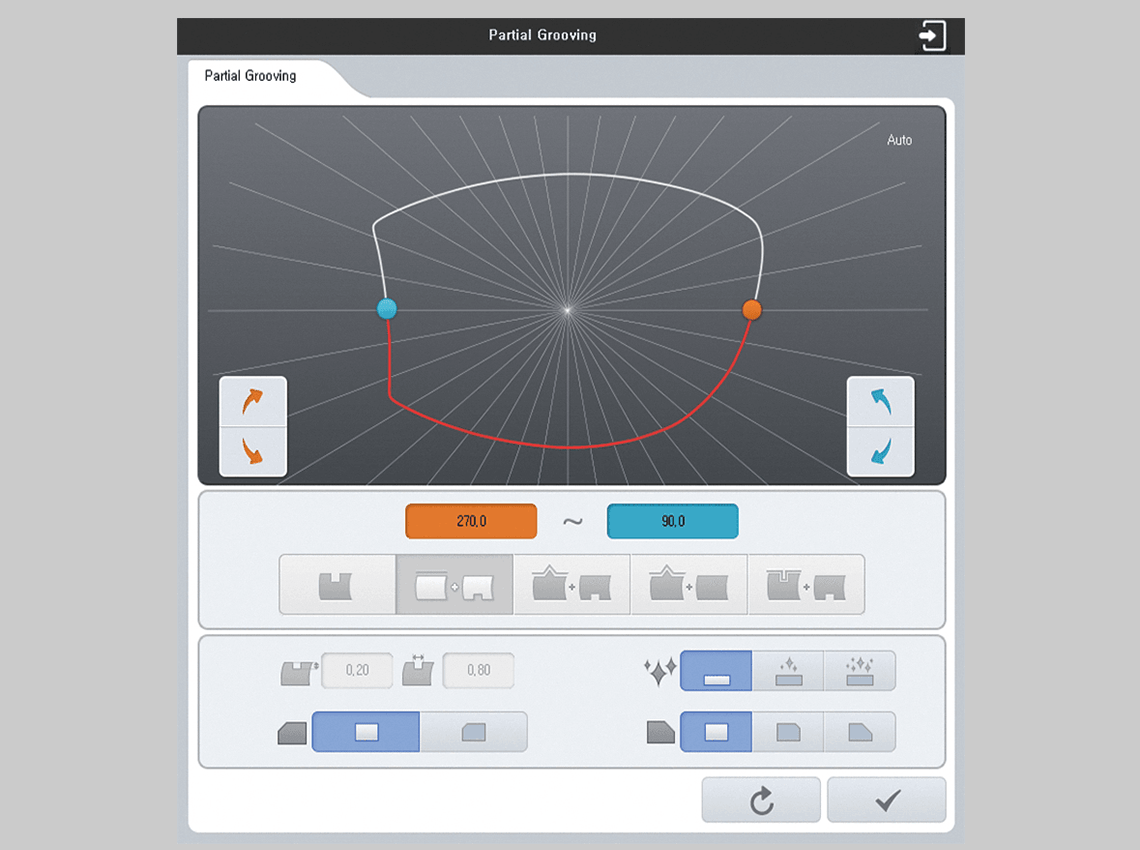

Step Bevel / T-Step Bevel / Beveled Top / Grooved Top

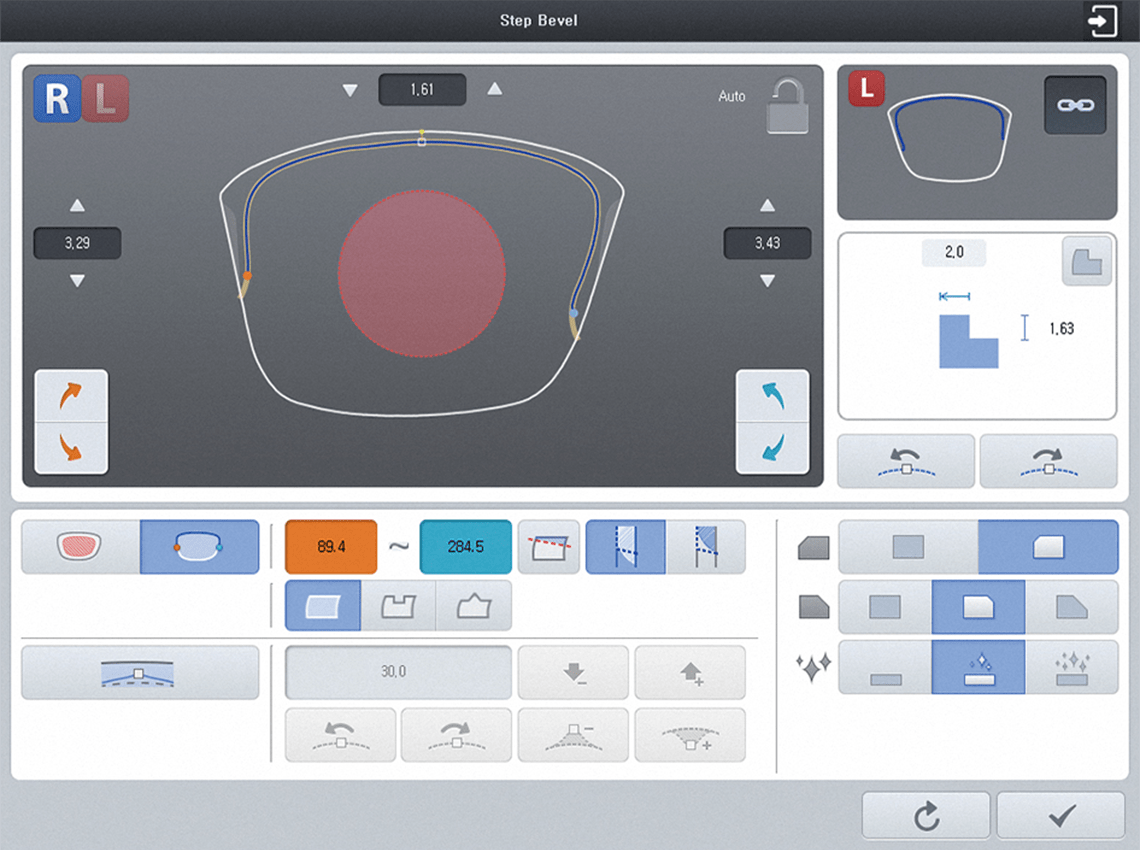

Achieving perfect fitting is possible

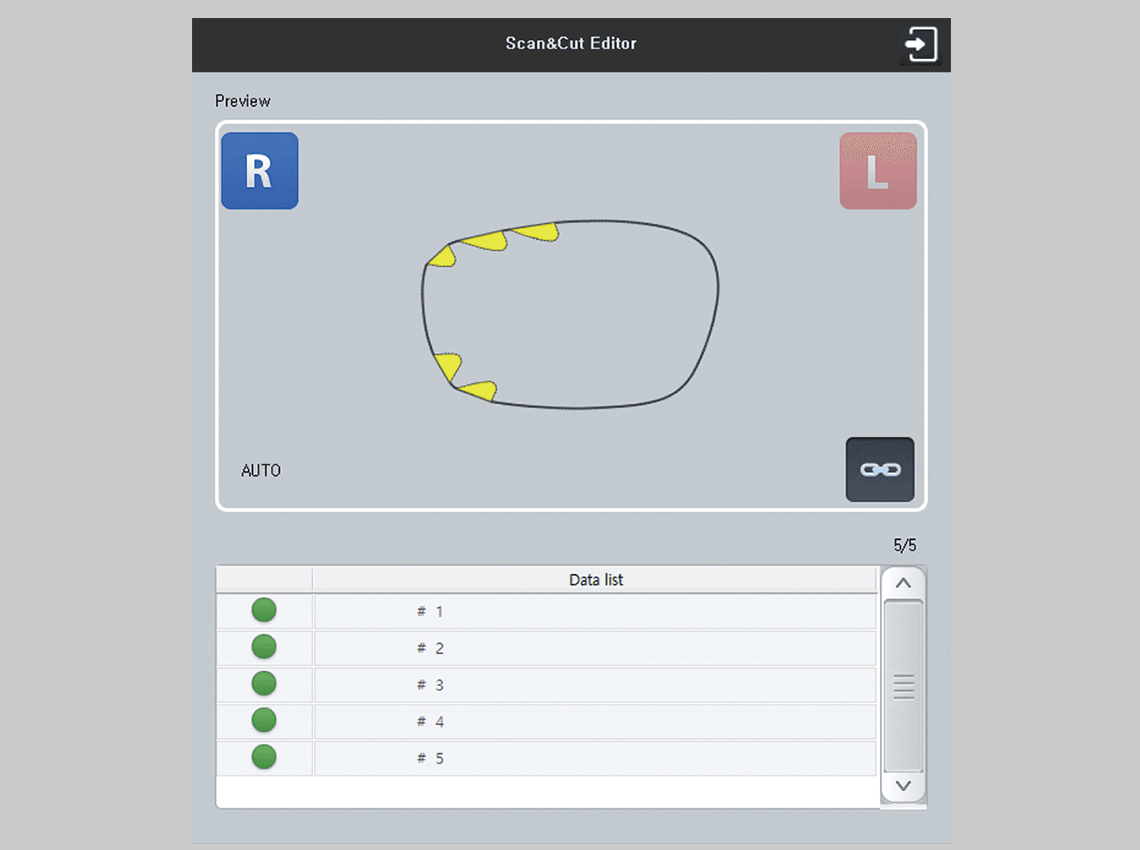

By supporting 4 types of 'complex processing, bevel, rimless, and grooving', users can perfectly finish fitting for various frames. The Silhouette brand as well as unique designs from various house brands can be scanned and processed with the optional Scan & Cut feature. Additionally, by selecting the Step Bevel option, you can perfectly process a wide range of eyewear, from High Curve sports goggles to Oakley Holbrook frames.

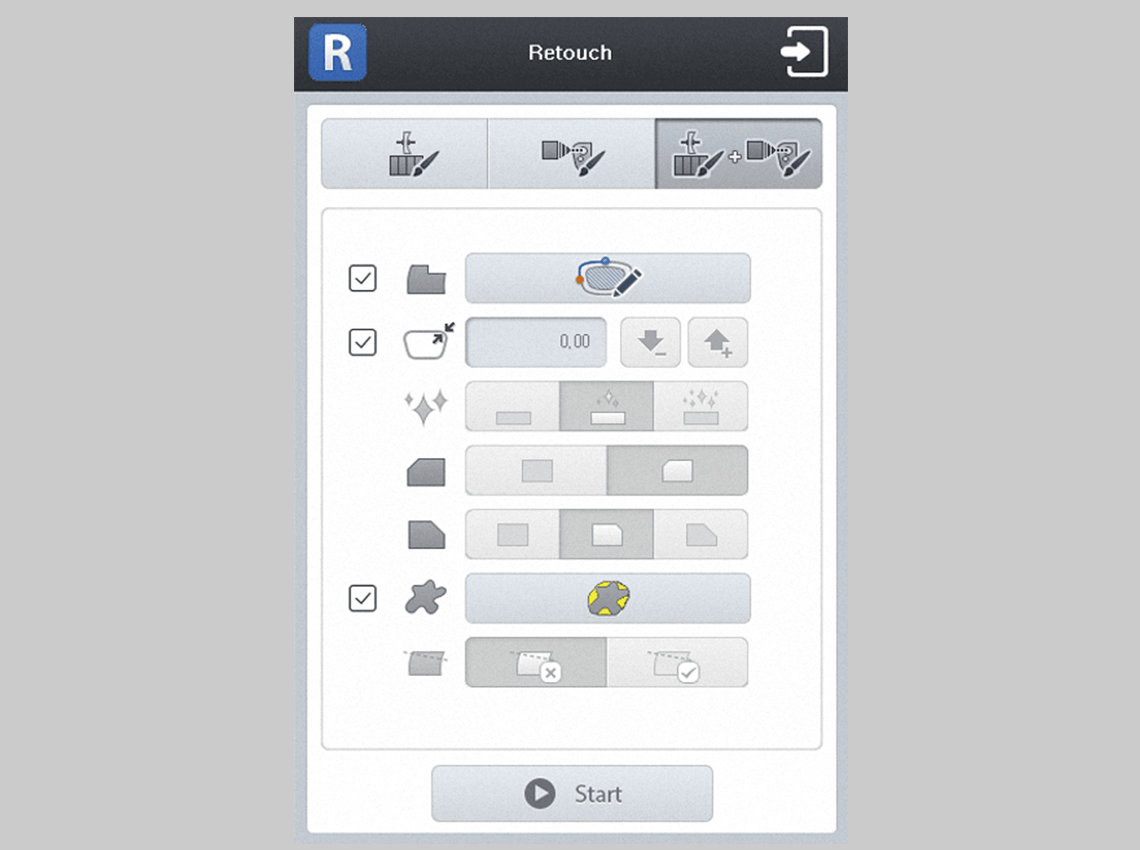

Retouch Mode can be utilized in a smart way

Retouch mode even enhances the efficiency by allowing wheel-edging, drilling as well as step beveling selectively in a smart way – e.g. If the bevel shape does not match the frame after processing, you can retouch the bevel height

Video

Huvitz MEMBERS

더 많은 안과컨텐츠를 원하신다면

휴비츠멤버스에 가입하세요.

Specifications

1. Key Features

Lens Material

Plastic, Polycarbonate, High index plastic, Glass, Trivex

Edging Tybe

Bevel, Groove, Rimless, Mini bevel, Partial bevel, Partial groove, Dual groove, Hybrid groove,

Asymmetric bevel, Semi-U bevel, Step bevel*

Edging Position

Front %, Front mm, Rear mm, Base curve, Auto, Manual (with 2D simulation and 3D preview)

Edge Options

Polishing, Saftety bevel, Safety mode

Buit-in Drilling **

Hole, Slot, Notch, Scan & Cut shape, Chemistrie Clip

Functions

Job manager, Digital pattern, Hole edtor, Asymmetric bevel editor, Scan & Cut shape editor

Step bevel editor, OMA import/export, CAD export, DCS/OMA compatibity,

Retouch mode (Normal, Drill-only, All)

Utilities

LCD tiling

Automatic edging room door

Edging room illumination

SD card storage (Memory card induded)

Barcode reader interface, Vacuum interface

Edging Size

Max. 90mm

MIn.flat edging : 18.5mm (without safety bevel)

Min. bevel edging : 20mm (without safety bevel)

Display

9.7 color TFT LCD(1024x768) with louch screen

Dimensions / Weight

540(W) x 472(D) x 580(H)mm

51.2kg (110V), 50.2kg (220V)

Power Supply

AC 100~120V / AC 200~240V 50/60 Hz

Power Consumption

1400VA

* 'N' type doesn't support step beveling. ** 'X' and 'N' types don't support built-in drilling.

2. Finishing Featrues

Wheel / Edger Type

RPGA (220V)

X

XD

N

RPA (110V)

XD

X

N

Wheel Combination

High-speed plastic roughing (220V: normal, 110V: super wide)

Hybrid finishing (Finishing + Asymmetric)

Polishing (Rimless only)

Polishing

Glass roughing

None

Plastic

Lens Material

Polycarbonate

Hi-index

Trivex

Glass

None

Mini Beveling

O

O

O

O

O

O

Asymmetric / Semi-U

O

O

O

O

O

O

Partial Grooving*

O

O

O

O

O

O

Hybrid Grooving*

O

O

O

O

O

O

Built-in Drilling

O

X

X

O

X

X

Drilling Machine Support

X

O

O

X

O

O

Step Beveling**

O

O

X

O

O

X

*No grooving support for glass material. **No step beveling support for glass and plastic, or CR39.

Related Products

FAQ

Q. What are the key features of the HPE-910 lens edger?

A. The HPE-910 is a premium lens edger equipped with a Step Bevel function, enabling precise processing of various high-curve frames, including high-curve sports goggles. It applies a high-power motor wheel to deliver fast and stable processing speeds, and supports a wide range of step bevel processing with 7 types and 5 edge styles, ensuring perfect lens fitting.

Q. In what situations is the Step Bevel function of the HPE-910 used?

A. The Step Bevel function of the HPE-910 is particularly useful when processing lenses for high-curve sports goggles that require deep steps and high curvature to match complex frame structures. It also enables uniform and stable processing for structurally demanding frames, such as the Oakley “Holbrook,” ensuring precise fitting tailored to each frame design.

Q. What lens materials and frames is the HPE-910 suitable for?

A. The HPE-910 can reliably process a wide range of lens materials, including plastic, polycarbonate, and high-index plastic. It is also suitable for various frame types, from high-curve sports goggles and structurally complex frames such as the Oakley “Holbrook,” to rimless frames, making it ideal for diverse lens processing applications.

Q. What is the Smart Retouch Mode of the HPE-910?

A. The Smart Retouch Mode of the HPE-910 allows selective reprocessing when the bevel shape does not perfectly match the frame after initial processing. By selecting only the required areas for correction—such as wheel processing, drilling, or step bevel processing—users can achieve precise fitting while improving overall work efficiency and finishing quality.

Q. What types of eyewear frame designs can be produced using the HPE-910?

A. The HPE-910 utilizes a built-in high-resolution camera to accurately recognize the shape and drilling positions of any demo lens, supporting a wide variety of eyewear frame designs. In addition, digitally scanned shapes can be freely edited on the demo lens image, allowing precise processing of frames with unique curves or distinctive designs.