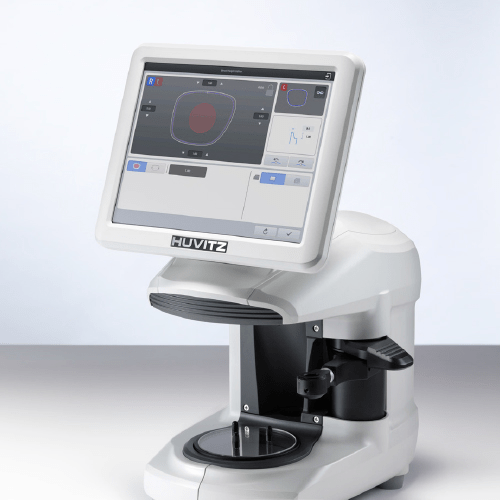

HPE-810

Lens Edger

Mid-range lens edger with Scan&Cut, custom processing house brand eyeglass frames

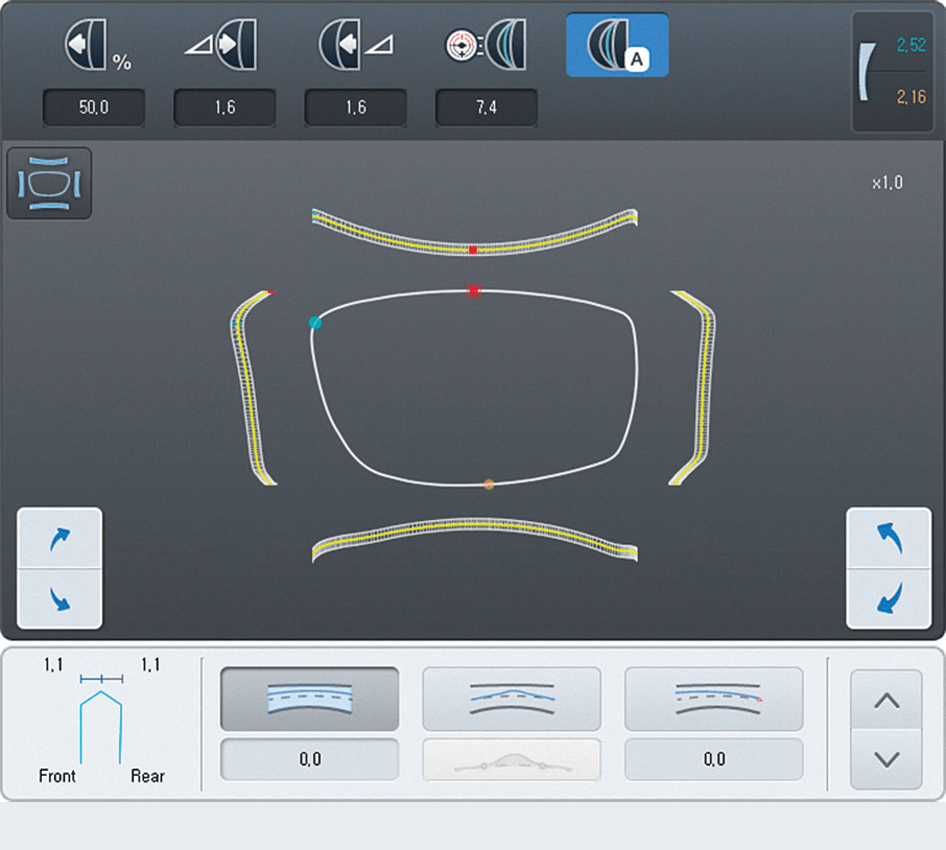

- Convenient 3D simulation with Automatic / Manual functions

- Powerful built-in Drill

- Various editing functions of Scan & Cut

MENU

Explore Details

Convenient 3D simulation

Easy to check the position of bevels/groove through 3D simulation. Auto positioning function reads frame and lens curve automatically and calculates to find the optimal position and start lens processing. Additionally, the manual positioning function allows the optician to adjust the position of the bevel / groove for the best result.

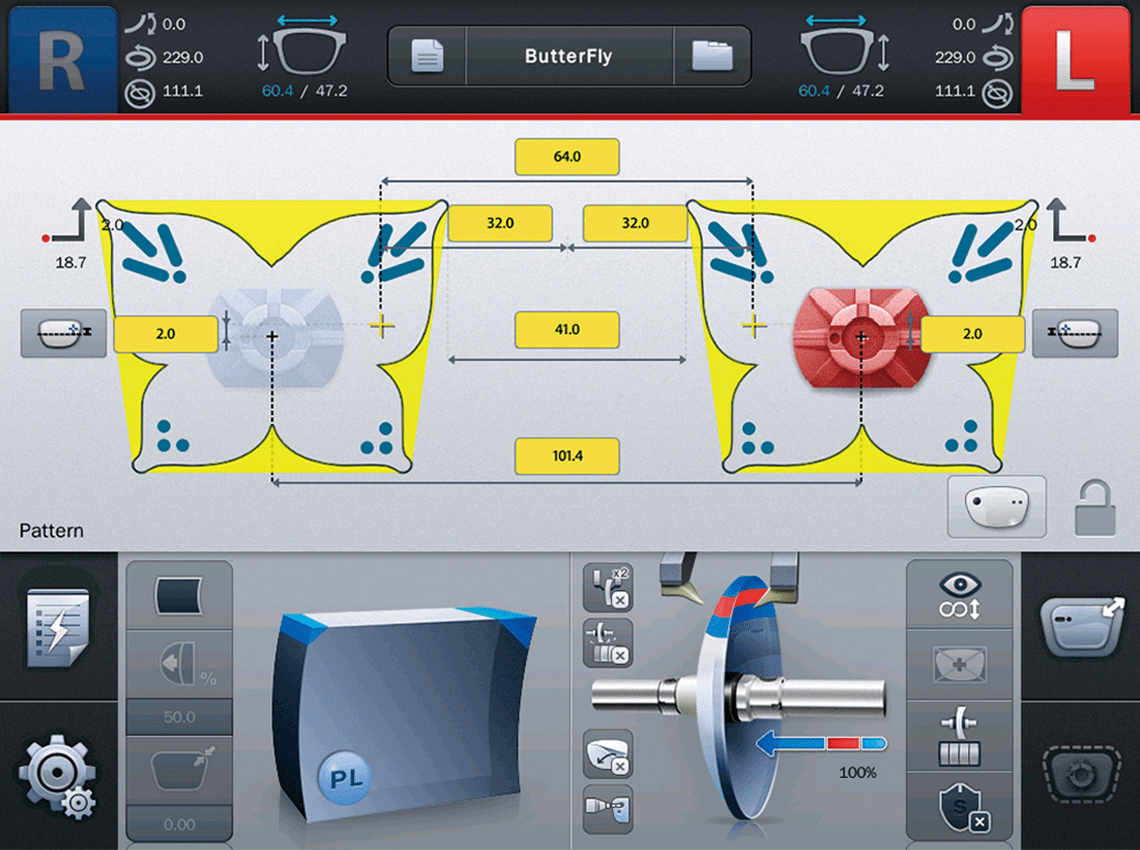

Powerful built-in Drill

Equipped with a high-output motor, the HPE-810 has more power and reduces the lens dispensing time. By easily handling hole editing functions that were difficult to attempt at once, the opticians can edit the holes of various designs more quickly and easily.

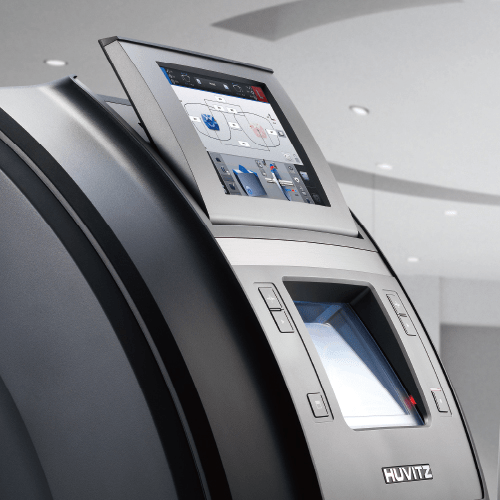

Various editing functions of Scan & Cut

Scan & Cut function supports processing all designs without any restrictions. Scan your design and fit it in your frame.

Basic Bevel : Flat, Normal, Partial, Mini, Concave, Retouch

Grooving : Normal, Partial, Dual, Hybrid

Scan & Cut(Option)

Video

Huvitz MEMBERS

더 많은 안과컨텐츠를 원하신다면

휴비츠멤버스에 가입하세요.

Specifications

1. Lens Material

Plastic, Polycarbonate, High Index Plastic, Glass, Trivex

2. Wheel

Diameter 150mm, RPG Type

3. Edging Mode

Beveling (Normal / Auto / Manual Mode, Mini Bevel Option)

Grooving (Normal / Auto / Manual Mode, Partial / Hybrid / Dual Grooving Option)

Flat Edging

Safety Beveling

Polishing

4. Functions

Job Manager, Digital Pattern, Hole Editor, Retouch, Bevel / Groove Simulation

Shape Mirroring, Easy Click, Concave Shape, Scan & Cut (Optional)

5. Utilities

LCD Tilting

Automatic Edging Room Door

Edging Room illumination

Simultaneous Bilateral feeling

SD Card Storage (Memory Included)

Barcode Reader (Optional)

Vacuum Interface (Optional)

6. Edging Size

Max : 90mm

Min : Flat Edging : 18.5mm (without safety bevel) / 23.0mm (with safety bevel)

Min : Bevel Edging : 20mm (without safety bevel) / 24.7mm (with safety bevel)

7. Drilling

Hole Type : Hole, Slot, Notch

Hole Size : Ø1.00~5.00mm

Hole Depth : Max 6.0mm

Range of Hole Drilling : Ø32.0~75.0mm from lens rotation axis

Slot Width : 1.0~5.0mm

Slot Length : Max 20.0mm

Tilting Mode : Automatic, Manual (0~30°)

8. Hardware Specification

HW Platform

GUI (1GHz), Motor (120MHz)

Display

9.7 inch Color TFT LCD(1024x768) with Touch Screen

Dimensions

540(W) x 462(D) x 597(H)

Weight

55kg

Power Supply

AC 100~120V / AC 200~230V 50/60Hz

Power Consumption

1200W(110V), 1500W(220V)

* Specification and design are subject to change without notice.

Related Products

FAQ

Q. What are the key features of the HPE-810 lens edger?

A. The HPE-810 is a mid-range lens edger that enables customized processing of a wide variety of designs, including house brand frames, through its Scan & Cut function. It is equipped with a 3D simulation system that allows easy switching between automatic and manual modes, as well as a powerful built-in drill, enabling stable processing even for lenses with complex shapes.

Q. What are the advantages of the Scan & Cut function on the HPE-810?

A. The greatest advantage of the Scan & Cut function on the HPE-810 is its ability to instantly scan demo lenses or frames, convert them into image files, and process a wide range of shapes without limitations. Using the shape editor, users can make fine adjustments such as reducing or removing vent holes. It also accurately supports designs that require concave grooving, such as handmade frames or distinctive house brand frames.

Q. How are errors handled during the Scan & Cut process on the HPE-810?

A. The HPE-810 is equipped with an error detection and correction system that minimizes issues during the Scan & Cut process. If a problem is found in the scan data, the system notifies the user and guides them to perform a simple rescan or manual correction. Through the intuitive GUI, users can easily identify the location of the error and recheck the accuracy of the automatic blocking function, ensuring stable processing.

Q. What types of lenses and frames are best suited for the HPE-810?

A. The HPE-810 is suitable for all standard lens materials, including plastic, polycarbonate, and high-index lenses. Its built-in tracer accurately scans various frame types—metal, plastic, and rimless—and delivers stable performance even when processing curved lenses. It is optimized for accurate and efficient processing of the lenses and frames most commonly handled in optical shops.

Q. Can the HPE-810 be used for high-curvature lenses?

A. The HPE-810 is designed to support processing of high-curvature lenses. Through precise 3D measurement and blocking systems, it detects changes in lens curvature and reflects them during processing. However, it is not as specialized for ultra-high-difficulty high-curve lenses as premium models such as the HPE-990. General sports sunglasses and moderately curved frames can be processed with stable and reliable quality.