Step-by-Step Guide to Lens-Over-Frame Sunglasses Processing Using HPE-990

One of the frequent concerns that opticians face is the processing of Lens Over Frame Sunglasses. Unlike general lenses, these feature more complex frame structures and a higher level of difficulty, which often makes them difficult to process directly in-store. As a result, they typically need to be sent out to a specialized lab or service provider.

Production times grow longer and costs increase, leading customers to question why the process can’t be done on-site.

The product that can solve this problem is the Huvitz Lens Edger HPE-990. The HPE-990 is the world’s first solution that allows Lens Over Frame Sunglasses to be processed directly in the optical shop. It helps opticians produce customized sunglasses more quickly and precisely without the need to outsource.

So how can an optical shop actually use the HPE-990 to make Lens Over Frame Sunglasses? Let us walk you through the step-by-step production process using the HPE-990.

Preparation Stage : Lens Preparation and T-Bevel Measurement

Step 1. Prepare sunglasses lenses and the Huvitz auto blocker HAB-910

To process Lens Over Frame Sunglasses, lenses with a base curve of 0 to 3 and a refractive index of 1.60 to 1.71 should be prepared. It is important to select the right base curve according to the frame shape. Also, prepare the Huvitz auto blocker HAB-910.

Step 2. Draw the Deep Step Bevel line

Use the demo lens mounted on the sunglasses frame to draw the Deep Step Bevel line.

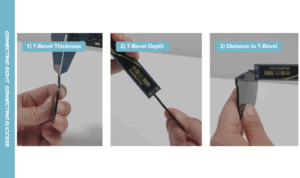

Step 3. Measure the T-Bevel

Use a vernier caliper to measure the T-Bevel thickness, T-Bevel depth, and the distance to the T-Bevel from the demo lens. These values are essential data to ensure a perfect fit between the lens and the frame.

1) T-Bevel thickness : Measure the thickness of the raised center part of the T-Bevel

2) T-Bevel depth : Measure the depth from the raised center to the front surface of the lens

3) Distance to the T-Bevel : Measure the distance from the front surface of the lens to the T-Bevel

Setting Stage : Lens Scanning and T-Bevel Data Input

Step 1. Scan the demo lens

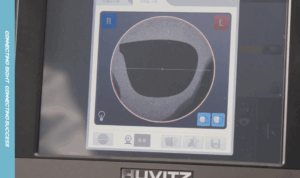

Place the demo lens with the drawn Deep Step Bevel line onto the HAB-910 Auto Blocker and perform the scan.

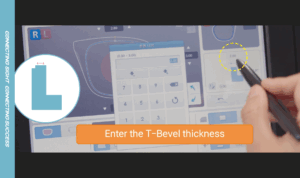

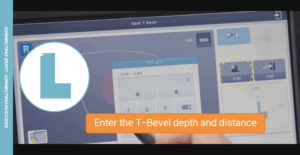

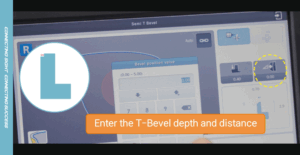

Step 2. Enter T-Bevel data

Enter the values measured in the preparation stage such as the T-Bevel thickness, T-Bevel depth, and distance to the T-Bevel into the Deep Step Bevel Editor. The Deep Step Bevel value is automatically measured by the HAB-910 Auto Blocker so there is no need to enter it manually.

Step 3. Lens blocking and data transfer

After blocking the lens, transfer the necessary processing data to the Lens Edger HPE-990.

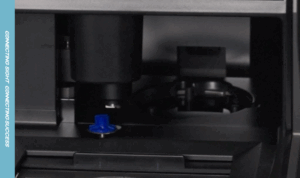

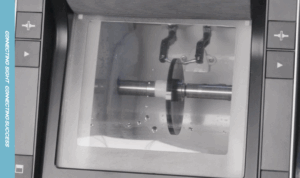

Processing Stage : Precision Processing with HPE-990

Once the setup is complete, place the prepared lens into the Lens Edger HPE-990. The HPE-990 then automatically performs precision processing and allows you to complete Lens Over Frame Sunglasses without outsourcing.

So how does the Lens Edger HPE-990 make it possible to process complex Lens Over Frame Sunglasses?

√ Deep Step Bevel processing

The HPE-990 can cut the lens edge up to 20mm in depth which allows it to securely handle frames with deeper lens-holding grooves.

√ Semi-T Bevel processing

It gently trims the edge of the lens to ensure an accurate fit even for frames that are difficult to mount using conventional methods.

√ Scan & Cut

By precisely scanning the frame and automatically designing an optimized cutting path for the lens the HPE-990 enables clean and accurate processing even for high difficulty Lens Over Frame designs.

Produce those challenging Lens Over Frame Sunglasses with ease using the HPE-990.

Learn more about the HPE-990 product information