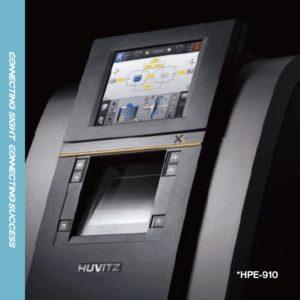

Processing Speed of HPE-990 Proven Through Comparison with HPE-910

The competitiveness of ophthalmic lens edging equipment ultimately comes down to two factors: accuracy and speed. The shorter the customer wait time, and the more lens orders processed in a day, the greater the need for a system that delivers fast yet stable performance. However, if speed is achieved at the expense of precision, it can result in poor finishing quality or even lens damage.

That’s why the true benchmark of performance lies in one question : “How fast can it go while maintaining quality?”

This is exactly where Huvitz’s lens edger HPE-990 provides a clear answer. Behind its fast processing lies refined engineering and precise technical details, which don’t just save time, but bring innovation that enhances overall workflow efficiency in real-world environments.

So how does the HPE-990 achieve such fast processing performance?

In the following sections, we’ll explore the key technologies behind the speed, as well as real-world comparison test results that show how it delivers both speed and quality at once.

What is the reason behind the fast processing speed of the HPE-990

The reason why the lens edger HPE-990 is drawing attention in the industry is not simply because it is fast. Its fast processing speed is made possible by structural design and technical detail that support its performance. In particular, the following three core technologies are key factors that enable the HPE-990’s remarkable processing speed.

① 1,250W / 5,000rpm Power Motor Wheel

: The HPE-990 delivers 1.7 times more power and 1.5 times higher rotational speed than its predecessor. Even at high RPMs, it maintains strong cutting force, ensuring both speed and precision with excellent stability.

② High-Speed Drill

: The high-speed drill operates at twice the speed of previous models and performs fast, precise Semi-T bevel edging even on complex shapes.

③ Hydrophobic Lens Processing Mode

: The hydrophobic lens processing mode is designed to automatically apply the optimal settings for pressure, speed, and wheel configuration, enabling fast and stable processing without any reduction in speed.

Speed Comparison with HPE-910

Huvitz conducted a direct comparison test between the HPE-990 and its predecessor, the HPE-910, under identical conditions and in the same environment.

< Lens Requirements >

* Super hydrophobic coated lens

* -8D, -2CYL, 75mm

* Plastic Lens

< Setting Requirements >

* Hydrophobic Mode(ON)

* Feeling After Roughing (ON)

* Blocking Position (Box Center)

< Test Results >

* HPE-990: Lens processing time – 3 minutes 52 seconds

* HPE-910: Lens processing time – 4 minutes 49 seconds

Even with the same lens and the same working conditions, the HPE-990 delivered results that were approximately one minute faster than the HPE-910.

While a one-minute difference may seem minor, in stores processing dozens of jobs per day, it leads to significantly higher throughput and reduced customer wait times, making the efficiency gains in real-world settings highly noticeable.

Design for Fast Processing – Balancing Quality and Speed

The lens edger HPE-990 is not designed to pursue speed alone. As processing speed increases, maintaining operational stability and finishing quality becomes even more critical.

* Deep Step Bevel

* Scan & Cut

* High-speed Drilling function

With these three features, the HPE-990 is capable of precisely processing even the most complex and challenging frame types, including lens-over-frame sunglasses, high-curve goggles, and sports sunglasses.

The HPE-990 is a high-end lens edger that offers a well-balanced combination of fast processing speed, outstanding quality, and operational efficiency.

Experience the fast processing speed of the HPE-990, which offers more than just time reduction and helps enhance productivity and competitiveness at your workplace.

[View HPE-990 Product Details]

> https://www.huvitz.com/en/product/hpe-990/